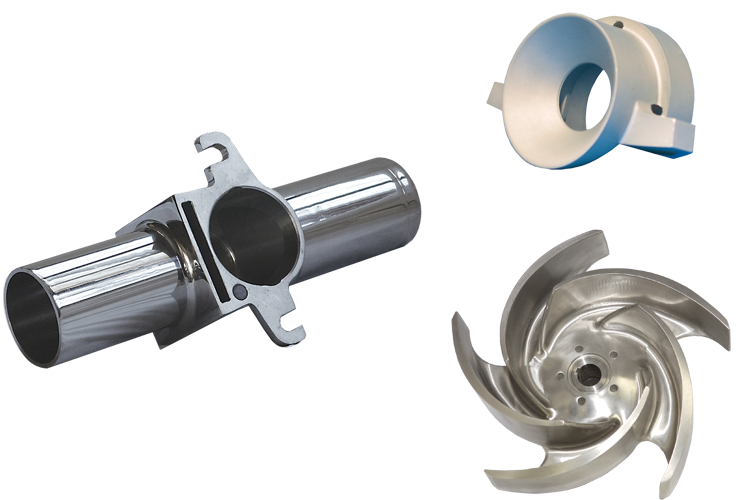

From a solid model to a metal prototype in 10-20 business days and best of all, no tooling required!

Rapid prototype casting combining the latest in 3D printing technology with the precision of the investment casting process. Wisconsin Precision Casting can deliver in just days either a 3D SLA model of your part for quick design validation or cast your design in metal so you can quickly evaluate its fit, form, and function.

LEARN MORE

Simplify Your Prototyping Process

Why limit yourself to the costly and often time consuming process of machining prototypes out of bar stock or fabricating prototypes as complex weldments? Simplify your prototype process by using investment castings from Wisconsin Precision.

No other process offers you more than the investment casting process.

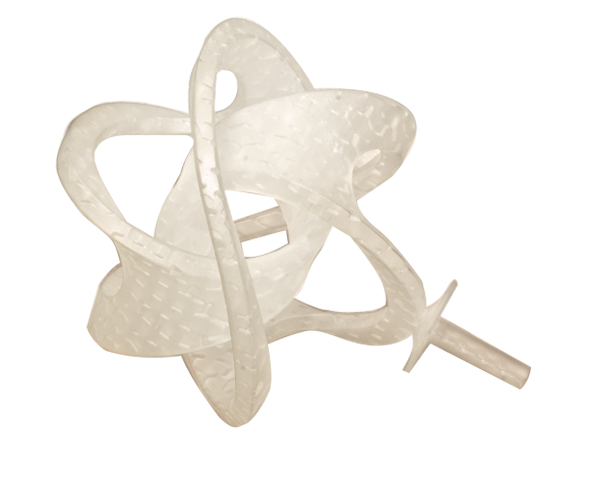

``Soliton`` - A mobius strip designed by Bathsheba Grossman

Investment Casting Advantages

Simple, low cost, quick turnaround solutions for your prototype requirements.

Greater Design Freedom

Greater alloy selection (over 150 ferrous and nonferrous alloys)

Over 180 Different Alloys to Choose From

Our broad selection of alloys allows you to utilize a material that is best suited to your performance requirements. No other process offers as many alloys to choose from as the investment casting process. Our metallurgical and engineering staff is available at any time to answer any questions you may have about a particular alloy or any application.

CLICK THE BUTTON BELOW TO VIEW ALLOY SELECTION